Choosing A Silicone Inflatable Seal Manufacturer

Selecting an inflatable seals manufacturer that can provide the level of service and product quality you want is critical when looking for a manufacturing partner for your silicone inflatable rubber seals.

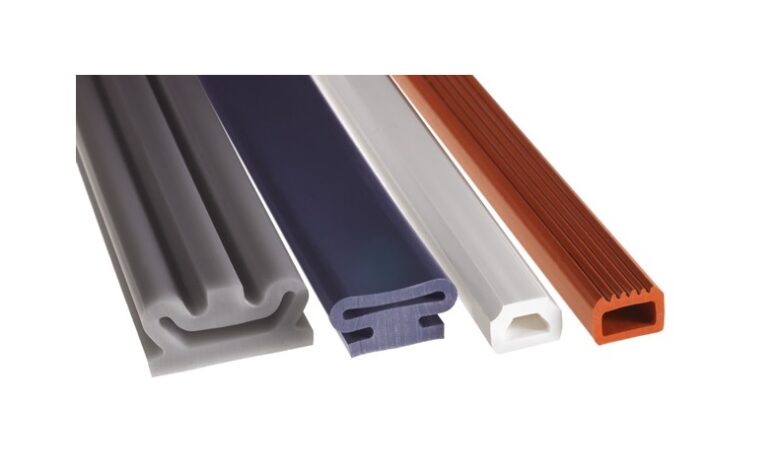

Silicone inflatable rubber seals, also known as pneumatic seals, are becoming increasingly popular across a wide range of industries, in part because these seals are the most effective method of sealing parts that move about one another and must be connected and disconnected at different times.

-

The ability to create anything from scratch –

Your inflated rubber seal will need to meet certain specifications. Inflatable rubber seals may be easily made with the help of a silicone rubber manufacturer with in-house design skills. It also provides a seamless transition from seal design to production.

-

Components in plenty –

Components from a broad range of industries are needed to create silicone inflatable seal solutions for a variety of businesses. The manufacturing partner you choose must be able to handle this demand swiftly and effectively. As an example, an inflatable seal manufactures stainless steel valves and silicone connection tubes that are molded to inflated seals to enable compressed air inflation.

-

The most up-to-date equipment –

Your silicone inflatable seals should be manufactured by a company that uses the newest technology and is capable of completing high-tech operations, and that invests in maintaining this level of service. As an example, the vulcanization process used by manufacturers creates a seal that may expand and contract as needed before the extrusions are molded together.

-

A wide range of testing options –

As a result of this capability, provided by inflatable seals manufacturer, you can be certain that your silicone inflated rubber seal will both meet and exceed your expectations.

-

Product performance –

Because of the wide variety of uses for silicone inflated rubber seals, they must be of the highest quality. The medical, pharmaceutical and food sectors need high levels of accuracy and performance. An Inflatable seal developed, can withstand pressures up to four-bar and temperatures up to 220 degrees Celsius, as well as greater temperatures for brief periods, in a wide variety of applications.

-

Compliance with industry norms and regulations –

All relevant national and international rules and certifications should be adhered to by your silicone rubber producer. This serves as a guarantee of continuous quality for you.

-

Product labeling –

Using inflatable seals manufacturer’s effective identification and tagging of items significantly enhances traceability, avoiding needless costs and waste. Using batch numbers, items may be tracked back to the compound stages of manufacturing. This guarantees that you get the same high-quality goods every time you order.

-

An all-inclusive in-house solution –

To have the best silicone inflatable rubber seals, you need to work with a silicone rubber expert manufacturer that can provide design, production, and testing all less than one roof. The inflatable seals manufacturer provides this level of service to assure the greatest degree of quality control for your goods, a faster order processing schedule, and improved cost-efficiency.

-

Conclusion –

These were some amazing and meaningful information on inflatable seals manufacturer.